Hangzhou Weixing Building Material Machinery Co., Ltd.

Main Products: Cement tile forming machine, Concrete tile making machine, Color tile making machine, Tile forming machine, Tile mould

Home > Company Introduction

Company Overview

Hangzhou Wei Xing Building Materials Machinery Co., Ltd., founded in 1999, is a professional color cement tile manufacturing equipment development company, with a strong strength of technology innovation. Products are under the operational guidance of the China Building Materials Xi'an Wall Materials Research and Design Institute, and State Building Materials &Industrial Wall and Roof Materials Quality Supervision and Testing Center. Products also have passed ISO9000 quality management system certification.

The company has shearing, bending, punching, pressing, milling, grinding, drilling and other types of large-scale mechanical processing equipment. According to the actual situation of development of the industry, they worked out an Enterprise Standard about encaustic tile equipment manufacturing: Q/HZWX01-2005, using AUTOCAD mechanical design, bringing in 5000KN large hydraulic machine, being a steel mould in the first time, ensuring that its technical specification. The processing of all mold forming from a machining center in one time to improve product accuracy, really achieved independent research and development of equipment & mould , installation forming integrated production structure, so that our product quality is far superior to the domestic industry standards.

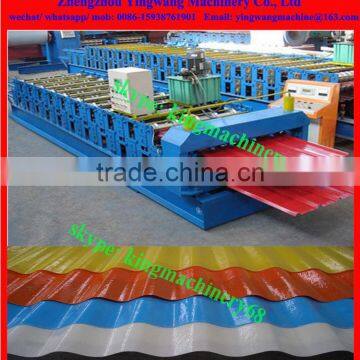

A new type of cylindrical tile molding machine, with high-speed of forming, high output and reliable performance. Using PLC (Mitsubishi technology) automatic control, hydraulic pneumatic, the production speed can up to 6-9 pieces/min, in a high yield and a better cost performance.

A new type of cylindrical molding tile forming machine, the underside of slid platform is made of semi-circular guide rail, compared with the square guide rail more stable and more wear-resistant.

Main oil cylinder and four-cylinder overall orientation, not only to improve the stability of the equipment, but also to extend the life of the mold.

A multi-purpose machine, through the replacement of mold, the machine can produce various types main tile and matching tiles. Products by pressure filtration pressure forming, structural beauty, variety, density, strength, size precision can meet the needs of various types of buildings are concrete products of quality products.

The Self-developed plate film can reduce the cost of cleaning up and oiling. The product has applied for a new use of patents. Patent No.: ZL200820085797 X. Company covers an area of 25,000 square meters, owns large-scale production workshop, has strong technical force, with professional quality and perfect after-sales service system, all of these things free customers from worries.

Products especially suitable for the development of small and medium private enterprises to get rich. Our aim is: your success, that is, the quality of our products and business ideas plus the best feedback. We will pave way for your future and make your trip smooth sailing before.

-

ManufacturerBusiness Type

-

2003Year Established

-

30,000-50,000 square metersFactory Size

-

101 - 200 PeopleTotal Employees

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

101 - 200 People Total Employees

-

Africa, Southeast Asia, Mid East, South Asia, Eastern Asia, South America, North America Main Markets

-

Ningbo, Shanghai Port of Shipment

-

Tile Making Machine Main Industry

Our Certifications

Showcasing our professional qualifications and recognized industry certifications.